By Mike Pickford

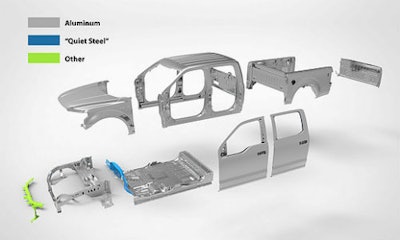

Peterborough, Ontario — July 5, 2016 — Lightweighting is still a concern for the OEMs, leading at least one expert to predict there will be a real push over the next decade to revamp the way vehicle exteriors are designed and made.

During a recent Auto Care Association webinar, IHS Automotive forecaster Michael Robinet told how there would likely be a “tremendous” shift towards the use of aluminum sheeting on vehicle bodies in the near future, a move that he expects will hit aftermarket producers hard.

“There’s more aluminum moving into the market … This is probably the most important trend that the aftermarket needs to understand,” Robinet said during the webinar, according to a report on Repairer Driven News.

While the use of aluminum for vehicle bodies has increased in popularity in recent years, Robinet believes an industry-wide transition could be on the horizon.

That will have an effect on specialized aftermarket products such as fenders and decklids, according to Robinet. During the webinar, he noted that it will be difficult for aftermarket manufacturers to recreate the precise shape of an aluminum sheet part following years of working with steel.

As a result, OEMs would be able to “take more control over the aftermarket,” for the time being. Robinet suggests such a move could take place as early as 2023.

However, others believe this will present aftermarket producers with a unique opportunity to revolutionize the way they do business. Ed Salamy, Executive Director of Quality Parts Coalition, said this is nothing the industry hasn’t faced before, with similar questions posed after OEMs made upgrades to side-view mirrors and a transition to LED headlamps several years ago.

“The aftermarket will also come up with a version,” Salamy said of advances in OEM parts, according to a report on Repairer Driven News.

As well as the shift towards aluminum, Robinet said he expects to see another significant change in the industry, this time focusing specifically on pickup trucks.

Following the success of the Honda Ridgeline, Robinet forecasts that more Asian OEMs will adopt a new strategy that is expected to shift truck bed production from its usual carbon fibre-reinforced plastic to composite material. The only real stumbling block to such a move is for developers to come up with a strong enough structure to support the bed, with Robinet suggesting that technology “is still evolving.”

Such a move could see domestic truck producers following suit over the coming years. Robinet claims a shift to composite is “very, very high” on US OEMs list for its next generation of trucks.

Robinet’s webinar presentation is available at this link.