Way back, during a time where people paid with cheques and wrote letters of correspondence on birch bark, I used to go shopping for groceries with my mother. As a child, I hated this task, so my buy-in was the acquisition of a magazine at the checkout. A Hot Rod or Car Craft magazine—some of which I still retain to this day.

Yes, I was going to paint cars when I got older. This was a certainty, as there was absolutely nothing cooler than the flames, scallops, stripes, and candies that graced the cover of these publications monthly. This is what I wanted to do for a living, a career, to have my work on the cover of a magazine, custom painting.

Much has changed over the years in our industry. Who would have thought that the candies of yester-year could be the actual factory finish on a vehicle that you buy brand-new, and who would have thought that the pearls and metallics would have the depth and shine out the door that they do.

The expense of learning back then was minimal. Today, the skill and technical knowledge far exceeds that of “tinting by eye”. We need let down panels, we need spray out cards, we need to be 100 percent informed on what the manual and SOP from the paint manufacturer say.

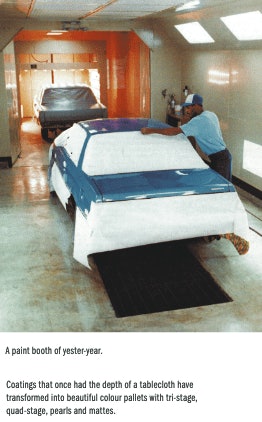

If one thinks back real hard, the lacquer and single-stage metallics of yester-year had the depth of a tablecloth.

Now if you haven’t guessed it by now, my beginnings in refinish are dated to times when the flash off of a coat of paint was timed by having a cigarette outside the booth, mainly on the multiple “overall” or “complete” refinishes we would do. It was not uncommon to do a full paint job on a vehicle that was a family grocery getter.

My father had his ’75 Olds’ Delta 88 refinished and patched up three times over its lifespan, with each time coming home with a surface texture, and depth, that resembled citrus fruit. This, however, was deemed acceptable to the masses.

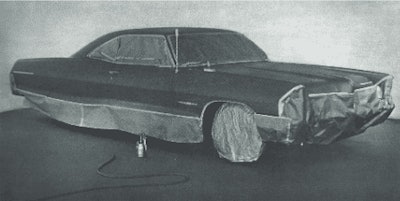

My training back then was live and on the floor. Started with prepping using lacquer primer and putty, sanding with a jitterbug sander sporting P180 on the hand numbing, chrome eating, window scratching, air-driven mechanical wonder. Masking all the trim, handles, chrome, and even the nameplates—yes nameplates, my favourite being the “Park Avenue” or “Buick Electra” script, so lovingly created by the General and shared with AMC. Masking tape, no fine line, not even a quarter inch at the time. Let us not forget the wonders of lacquer finish that GM flogged to the very end, not to mention the dispersion lacquer used on the Grand Nationals….

Sand it down with P400, spray some primer hoping it wouldn’t wrinkle, then bake it under the lights only to have it re-flow and come out looking like deep wet black paint, let’s sand all over again. Then off into the crossflow booth with puddles of water on the floor from wetting it down to keep the dust down from the preppers sanding just inches away from the filters.

There it was, the “North American Land Yacht” in all its prepped beauty, ready for a coat of high-end, single-stage acrylic enamel.

The test of a good painter back then was if you could spray a single stage metallic light blue without the trademark visual of tiger stripes and clouds (modelling or blotchiness). Also, could you get the centre of that hood as wet and shiny as the sides, without leaning into the wet finish on the fender.

And just as you thought it was all over, there was that fly that would find its way into the fresh surface of that beautiful Olympic pool-sized hood only to succumb to the fumes and perish during it’s two-foot marathon attempt at the backstroke.

Next, we would push it into the drying room to wait patiently for the cycle of time it took for the heat lamps to dry the finish to that satiny hazed glow known to many as a single-stage metallic.

Remember the “spot repair” back then, mixing cocktails with a smoke in your mouth, dipping the stir stick into the can knowing that if all else fails for colour, just add some green, fixes everything. Tinting by eye, little bit of this, little bit of that, cocktail the reducers and (if it had any) hardener, using RM with Ditzler, or DuPont, if things were out of stock—good enough to rock and roll!

Do you have a clear picture of what once was? You young ladies and gentlemen of the trade are fortunate enough not to experience that remarkable wonder in time, coupled with the transition of plastics and two-stage products? Oh, what a time it was.

Fast forward to today. Beautiful colour palettes with tri-stage, quad stage, pearls, and matte finishes. I spent decades on getting that “wet look” out of the booth…and now people want matte, go figure. However, that aside, matte finishes present their own set of challenges.

So why the trip down memory lane? Times are changing, training and development are changing. Back in the day, we didn’t have paint manufacturer-based training. Our suppliers dropped off product and chatted with us, showed us the new goods, the rest we figured out.

The expense of learning back then was minimal. Today, the skill and technical knowledge far exceeds that of “tinting by eye.” We need let down panels, we need spray out cards, we need to be 100 percent informed on what the manual and SOP from the paint manufacturer say.

This all comes at a cost, not to mention the cost of materials. At more than $400 for a gallon of hardener, you no longer can “cocktail something.” Over my years I was able to hone my craft quite well. I could lay a “splash” with the best of them, never made a magazine cover, but did do many a show finish.

The point here is, that was then and this is now. With the refinish role what it is and the actual fact you only get one shot at it each time (redos will destroy your profit margin), and you can’t “bury” it (never could really, defies scientific logic) it is very wise as a business to be aware of the cost involved with each colour, as they vary considerably across the rainbow. Be fully aware of the actual time required for your painter and prepper to get that vehicle through the cycle. If you’re forgetting the tri or quad extra, let down panel time, dee nib and finesse—remember the fly… they are still out there—then you are doing a disservice to your staff and business.

In my opinion, and you are entitled to my opinion, the delayed gratification of a fine refinish job is one of the best forms of advertising out there for your shop. If you want to spend money on advertising, spend it on your paint department. What better place than an actual subliminal rolling billboard backed by a vocal presenter, your satisfied customer.