Toronto, Ontario — Both Bentley Motors and Ford Motor Co. made 3D-printing announcements this week, with the former announcing its exploration in 3D printed vehicle components, down to powertrains, and Ford releasing open-source files for customized interior accessories.

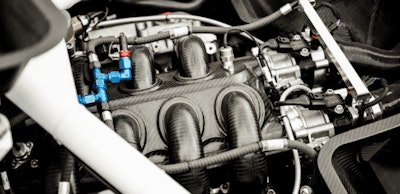

Bentley’s announcement came alongside an investment in the automaker’s additive manufacturing (AM) capacity at its Crewe, England, factory, where all of its models are assembled. The AM unit has been tasked to create physical components for several prototype Bentleys, down to full-scale powertrain and aerodynamic wind tunnel models.

The automaker said the Continental GT raced and broke records in last June’s Pikes Peak hill climb featured the AM technologies, with custom 3D-printed Inconel exhaust manifolds.

The automaker said 3D printing holds the power to halve parts costs and, by operating ’round-the-clock, the facility will be able to produce thousands of components using more than 25 materials.

“[Our] approach to additive manufacturing is industry-leading and the facility is quickly becoming a cornerstone of our Dream Factory ambitions,” said Peter Bosch, Bentley’s manufacturing head. “As we look to the future, there really is huge potential to where this advanced technology can progress, including having a greater ability to personalize parts for our customers and further enhancing the individualization programme offered on every car.”

In a similar approach to Bentley’s personalization goals, Ford has opened a trove of personalization alongside its release of open-source CAD files for customers to 3D print accessories for the Maverick pickup truck.

The files are for the Maverick’s Ford Integrated Tether Systems (FITS), a series of slots at the rear of the centre console and the under-seat storage bins that allow for customization with a wide variety of accessories, from dog water bowls to (likely non-functional) mini Yeti coolers.

Ford had already announced its intention to release the files since before the Maverick entered production, but it’s not the only project the automaker is exploring in the realms of 3D printing; the automaker has been dabbling with the idea of 3D printed car parts for the Ford Shelby since 2018.

The automaker also recently teamed up with HP to recycled 3D printed waste into end-use automotive parts in what it deems to be an industry first. Through the partnership, recycled 3D printing material will be converted into injection-moulded fuel-line clips for use on the automaker’s Super Duty F-250 trucks, with a goal of improving sustaining credentials of the firm’s manufacturing operations.